ENVIRONMENT

Our business is certified to the ISO 14001 environmental management system and successfully converted to the upgraded ISO 14001:2015 standard in 2019. This provides the framework upon which we minimise the impact of our activities and processes on the environment and local communities.

GREENHOUSE

GAS EMISSIONS

Greenhouse gas emissions (GHG) associated with manganese alloy production arise from power generation, fuel combustion, and the use of carbon-containing agents during smelting. Through our participation in the United Nations Framework Convention on Climate Change’s GHG emissions reduction project, we have over the years reduced our CO2

emissions by more than 100 000 tonnes per annum. Our ongoing emissions reduction plan involves sustained investigation into improved electrode assembly designs and other technologies that will enable us to reduce our total emissions.

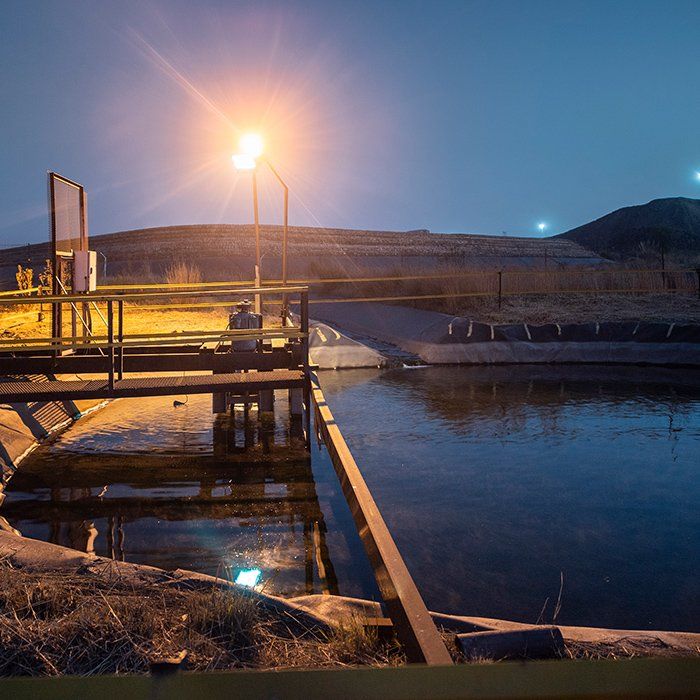

WATER

Our business is situated in a water-stressed region which means that we must do everything necessary to protect this scarce and precious resource. We operate a closed loop water system which means that no water used in our processing and cooling activities is discharged into the environment. Our water management interventions are guided by our integrated water use licence. Process water and surface runoff is diverted into pollution control dams for later reuse in various applications, including metal recovery and dust suppression.

AIR QUALITY

Large-scale mining, power generation and industrial activity has resulted in our region being declared a national air pollution hotspot. Continuous infrastructural improvements and the implementation of new technologies have enabled us to continually reduce our impact on air quality.

We monitor emissions in the form of NOx, N02, SO2, CO and CO2 on a monthly basis and these are measured against the limits set out in our Atmospheric Emission Licence and legislation. Levels are reported annually to the Department of Environmental Affairs through the national emissions system. Air quality controls include the replacement of baghouse dust bags every two years, dust suppression using water and other suppressants, the installation of e-samplers both on site and in our closest host community and dust fallout monitoring.